Ship is always in a surrounding of sea water, sun exposure, wind erosion, especially the deck. In addition, due to human activities and mechanical operations, the deck is often subject to stepping friction and crushing wear, and it is easily polluted by various oily, acidic and alkaline media.

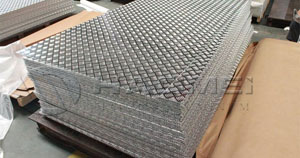

Therefore, the ship deck material should be of excellent corrosion resistance, water resistance, weather resistance, anti-skid property,abrasion resistance and adhesion. Which kind of aluminum sheets satisfies the requirements? 6061 stucco embossed aluminum sheet is an ideal choice. It is of excellent corrosion resistance, weather resistance and non-slip resistance. More importantly, it is easy to process.

Therefore, the ship deck material should be of excellent corrosion resistance, water resistance, weather resistance, anti-skid property,abrasion resistance and adhesion. Which kind of aluminum sheets satisfies the requirements? 6061 stucco embossed aluminum sheet is an ideal choice. It is of excellent corrosion resistance, weather resistance and non-slip resistance. More importantly, it is easy to process.

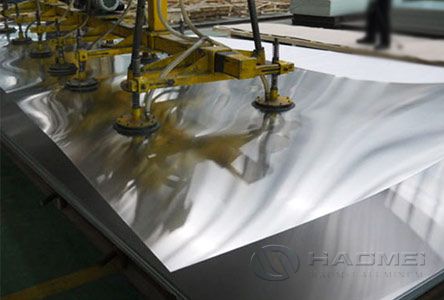

What processing technologies do we have to ensure the quality of 6061 aluminum plate? We have two quenching lines to achieve continuous quenching , improving production speed and ensuring stable product performance at the same time. The whole process only take 8- 16 hours, greatly shortening the production circle.

We choose Italian Herkues grinding machine equipment, ensuring the precise operation of the rolling equipment, thus improving the surface quality of the embossed aluminium sheet. The product not only has high gloss, but also has no visible defects.

We choose Italian Herkues grinding machine equipment, ensuring the precise operation of the rolling equipment, thus improving the surface quality of the embossed aluminium sheet. The product not only has high gloss, but also has no visible defects.

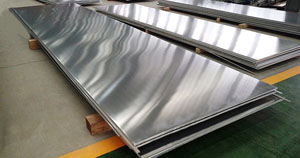

With such advanced processing craft and equipment, our 6061stucco embossed aluminum sheet is of novel pattern, light weight and excellent durability. Its tensile strength reaches 200N per square millimeter and it has high elongation, which is higher 10% than the average level.

Original source: https://www.hm-alu.com/a/whats-the-advantage-of-6061-embossed-aluminum-sheet-in-shipbuilding-industry.html

Original source:

Original source:  The deck is an important component of the hull, separating the hull into upper, middle and lower layers. Because of close contact with air and sea water and frequent human activities, it requires deck material have good corrosion resistance, water resistance, weather resistance and good adhesion. Besides, it also should have good slip resistance, wear resistance and corrosion resistance.

The deck is an important component of the hull, separating the hull into upper, middle and lower layers. Because of close contact with air and sea water and frequent human activities, it requires deck material have good corrosion resistance, water resistance, weather resistance and good adhesion. Besides, it also should have good slip resistance, wear resistance and corrosion resistance. Curtain wall is a good protection for the overall structure of the building. Among various plate materials, stucco embossed aluminium ceiling is more popular due to its stable performance, beautiful appearance and convenient installation.

Curtain wall is a good protection for the overall structure of the building. Among various plate materials, stucco embossed aluminium ceiling is more popular due to its stable performance, beautiful appearance and convenient installation.

A third factor to be considered is that formability of a specific alloy can be found in the percentage of elongation and the difference between yield strength and ultimate tensile strength.

A third factor to be considered is that formability of a specific alloy can be found in the percentage of elongation and the difference between yield strength and ultimate tensile strength. 1. It is cheap, durable and light.

1. It is cheap, durable and light.