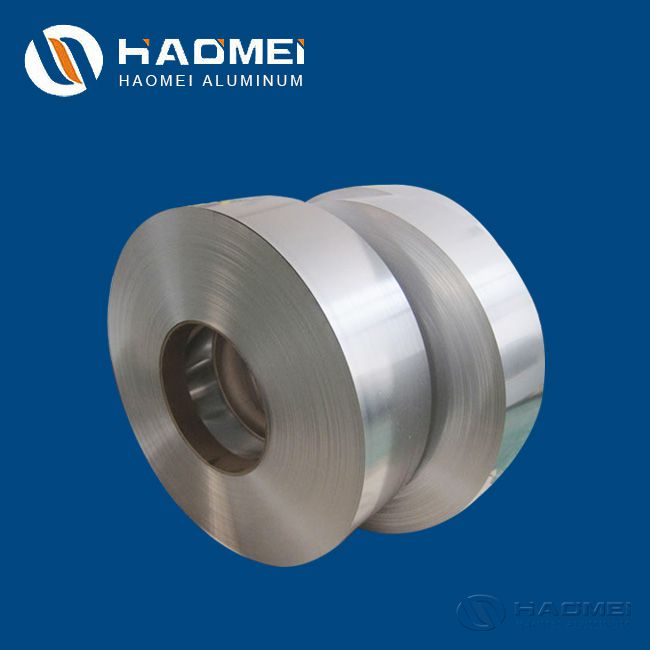

There is no authoritative statistics on how high the proportion of aluminum strips replacing copper strip as the raw material of transformer winding. Bu in the actual production, most transformer manufacturers has adopted aluminum strip.

This not only guarantees the normal performance of the transformer, but also It also fundamentally saves costs and lowers the overall transformer price. The large producers such as Siemens and ABB has used aluminum strips for transformer winding.

Why will aluminum be used to replace copper on transformers? That is because aluminum strip for transformers has strong economic efficiency compared with copper strip. There is data from one Chinese transformer manufacturer:

If aluminum strip is used for winding, the production cost is about 85,000 RMB, while if it is copper strip, that will be 105,000 RMB. The cost differs by about 20%. The use of aluminum strips in transformer has completely lower the the sales price of transformers and ensured the profitability of transformer producers.

Will aluminum strip bring security risks? In this aspect, an electromechanical technical engineer says, its safety can’t be simply judged by whether it uses copper or aluminum as the raw material. Because the production of all products is strictly in accordance with national standards, and the quality is determined according to the production control management of each enterprise.

Because in liquid and solid insulated transformers, aluminum strip conductors will not oxidize, and their chemical properties will not change, its safety is just same as the copper strip. As long as the quality and performance of the product can be guaranteed, whether it is copper strip or aluminum strip, the function in the transformer is the same.

The edges of aluminum strip produced by Haomei, aluminum strip supplier, have been processed with high precision to achieve an advanced level of no burrs and a resistivity of less than 0.028.

Original source: https://www.hm-alu.com/a/a-new-trend-aluminum-strip-for-transformer-winding-replacing-copper-strip.html