Antibiotic bottle caps are divided into two kinds: antibiotic aluminum caps and antibiotic aluminum-plastic combination caps. Most of the aluminum-plastic composite lids for antibiotic bottles are stamped from aluminum alloy plates. When it is in production, the punching die can be driven by the punch to punch.

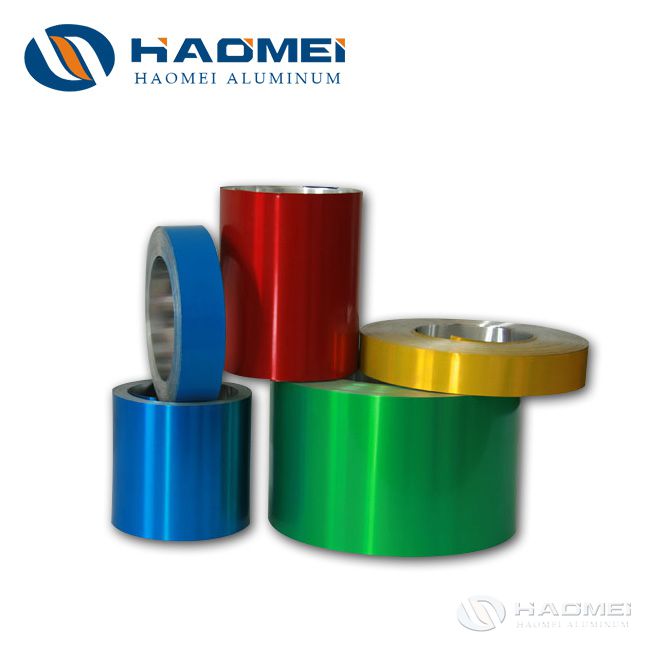

Different sizes of aluminum-plastic composite caps require different specifications of aluminum closure sheets for production. According to whether the aluminum alloy sheets for closure is coated or not, the aluminum cover is divided into three types: ordinary aluminum cover, single-coated aluminum cover and double-coated aluminum cover.

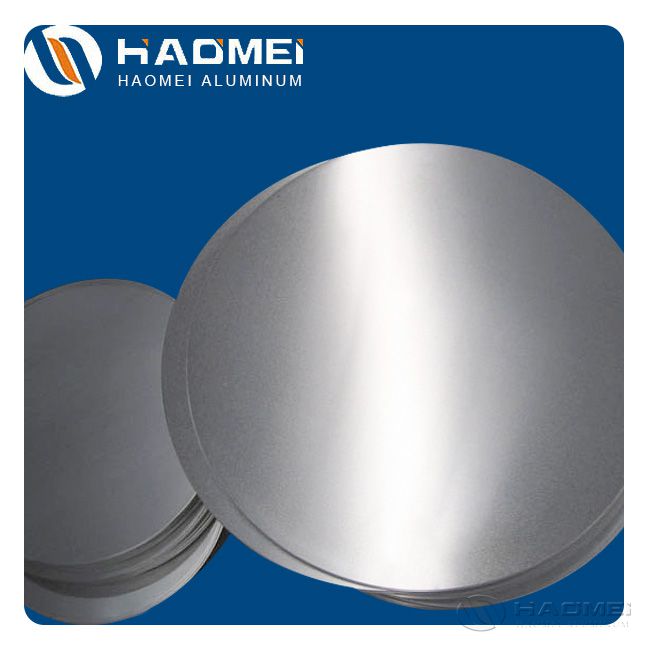

The thickness of the aluminum alloy sheet for closure is also an important reason that directly affects the strength of the aluminum cap. The thickness of the aluminum bottle cap material changes with the outer diameter. Generally, the thickness of aluminum closure sheet is 0.18-0.21mm for the caps of with a diameter of 13-20mm; 0.23-0.25mm for 28-33 mm.

Aluminum bottle cap material plays an important role in the beverage and medical industries. So, what are its advantages?

1. It has good airtightness and has a good protective effect on the product.

2. The aluminum caps packaging has anti-theft function, which can prevent unpacking and forgery, and ensure the quality of the product.

3. Aluminum bottle cap material is Compared with other bottle cap material, it is of high quality and low price.

4. It has the advantages of convenient use, improved packaging, and diversification.

5. It has high aesthetics. As an integral part of the packaging, aluminum caps can make the goods more attractive.

As an aluminum bottle cap material manufacturer, Haomei Aluminum has different kinds of aluminum alloys. 1060 aluminum sheet is often used to make aluminum-plastic caps.

Original Source: https://www.alumhm.com/a/aluminum-closure-sheet-for-antibiotic-bottle-caps.html