Aluminum alloy has good electrical conductivity and workability, and is an excellent heat dissipation material, suitable for various power products such as high-power substations, communication power supplies, purification power supplies, radio and television transmitters, inverter power supplies, etc. It is also used in the field of electronic products such as automatic control instruments.

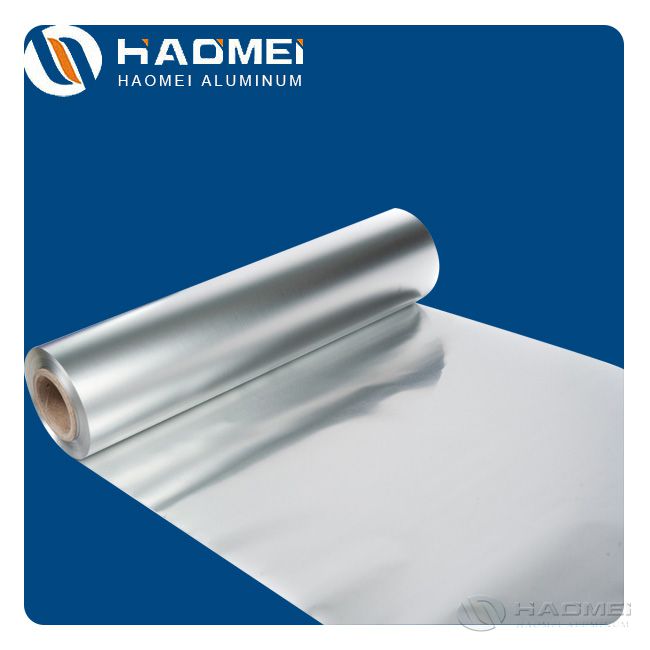

The production process of electronic foil includes: melting and casting- soaking- hot rolling- pre-annealing- cold rolling- intermediate annealing- cold rolling- foil rolling- slitting- performance testing- packaging. The common alloys are 1100A, 1050H18, 3003, 3004, 3005, 3104, 3105, etc. The specifications are 0.02-0.05*500mm.

To ensure the quality of electronic aluminum foil, Haomei Aluminum introduces a series of advanced equipment:

1. Adopt Siemens’ full digital system to precisely control the thickness of the industrial aluminum foil.

2. We have 40 tons nitrogen annealing furnace with stable function. It can achieve precise control of furnace temperature, uniform annealing, and improve product surface quality. At the same time, when performing subsequent processes such as anodizing, it can be colored uniformly and reduce color difference.

3. We adopt Zhuoshen foil rolling mill and ANDRITZ profile rolls, which provides a guarantee for achieving a good shape. We also adopt full hydraulic control, with high-precision pressure sensor and servo valve to realize the minimum roll gap.

4. We adopt vertical slitting machine with fast speed and high precision. The machine adopts hard-toothed gear transmission, which has high accuracy and good stability.

Haomei Aluminium has different types of aluminum foils for different applications. Welcome to leave message below to get a quote.

Original source: https://www.hm-alu.com/a/the-common-alloys-of-electronic-foil.html