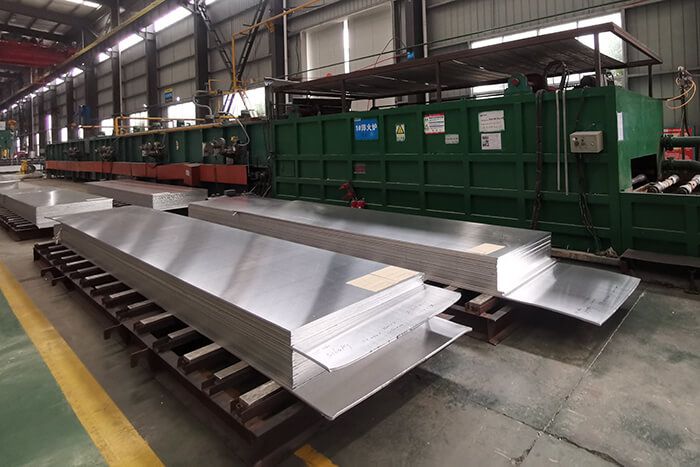

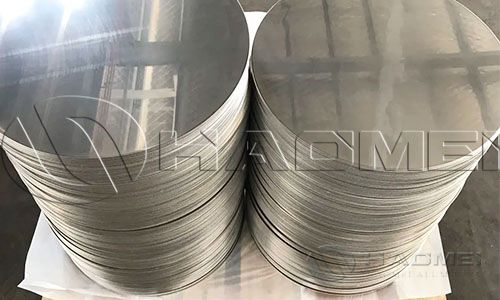

Los discos para aluminio son de ricas aplicaciones. Los dos primeros son para utensilios de cocina y señales de tráfico.

Discos de aluminio para utensilios de cocina

La gama de materiales metálicos para fabricar utensilios de cocina es muy limitada, porque los utensilios de cocina requieren buena conductividad térmica y estabilidad química, de lo contrario, provocarán cambios en el sabor de los alimentos. Muchos metales conducen el calor lo suficientemente bien, pero son demasiado inestables químicamente para ser adecuados para el procesamiento de alimentos.

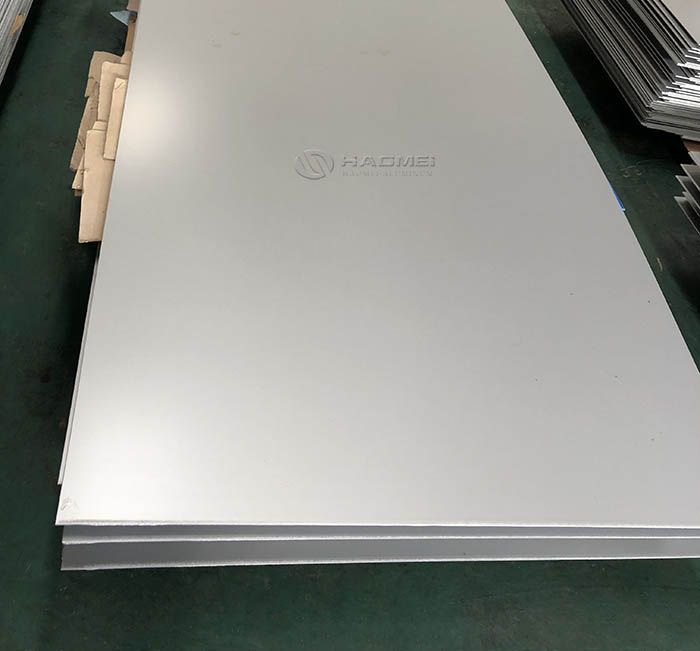

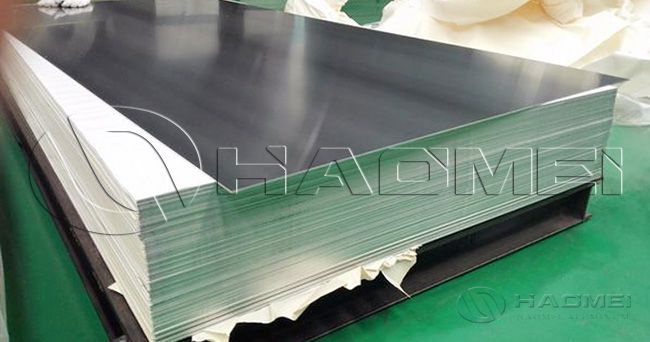

La chapa redonda de aluminio es un metal con una excelente conductividad térmica. No se oxida y es resistente a muchas formas de corrosión. Es un metal de uso común para utensilios de cocina. Está comúnmente disponible en forma de embutición profunda, fundición a presión o anodizado. La placa de aluminio redonda de embutición profunda se usa ampliamente en discos para hornear, bandejas de jugo, moldes para pasteles, ollas para sopa, ollas a vapor, moldes para pasta e incluso sartenes, etc.

El aluminio adecuado para estirar es principalmente aluminio deformado como 1060, 3003, 5052, etc. Además, los temples también tienen un gran efecto en el efecto de embutición profunda del círculo de aluminio. Como todos sabemos, durante el procesamiento, el círculo del disco de aluminio debe recocerse para lograr diferentes grados de suavidad y dureza.

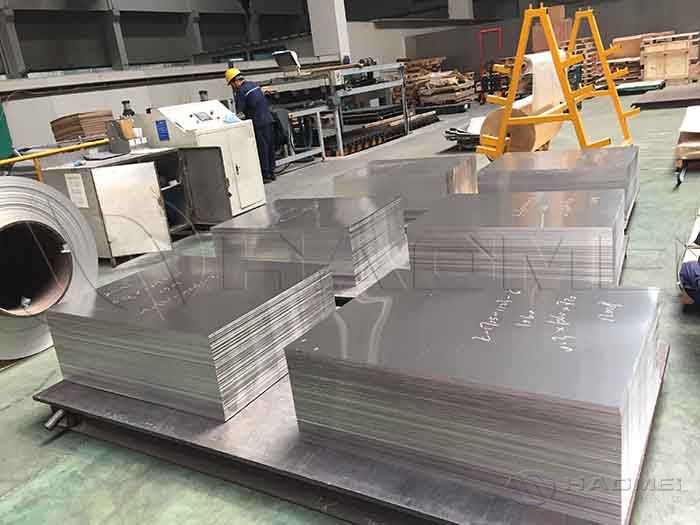

Círculo de aluminio para señales de tráfico

La lámina circular de aluminio es ampliamente utilizada en el campo de las señales de tráfico. Con el aumento del tráfico, muchos países han adoptado carteles pictóricos para promover el turismo internacional y reducir las barreras causadas por las diferencias entre los dos idiomas, mejorando así la seguridad del tráfico. Las aleaciones generales son 1060, 3003, 3004, 5052, etc.

Composición de las señales de tráfico

Por lo general, se compone de una placa base de letrero, una superficie de letrero, una columna, sujetadores, una base, etc. La placa base de letrero es en realidad una lámina circular de aluminio. Entre ellos, el material más utilizado para la elaboración de rótulos son los discos circulares de aluminio. Bienvenido a dejar un mensaje para consultar el disco de aluminio precio.

Los discos de aluminio se utilizan en los siguientes campos:

| Señales de tráfico reglamentarias | Señal de tráfico de advertencia | Orientación |

| cartel de la calle | señales de guía de ruta | señal de carretera |

| cartel de la escuela | cartel de bienvenida | designación internacional |

| señales de tren y tren ligero | señal de primeros auxilios | señal temporal de control de tráfico |

Original source: https://www.placadealuminio.es/a/los-dos-usos-principales-del-disco-para-aluminio.html