Although the familiarity of dye sublimation printing technology is not comparable to the two basic printing technologies of inkjet and laser in the office field, it has unique advantages in photo output. The image resolution is extremely high, the color transition is natural, and it is easy to save. What is the unique principle of sublimation printing technology?

Sublimation is to use sublimation from gaseous state to solid state and solid state to gaseous state without intermediate states. The solid pigment used in the printer is directly sublimated into the gas phase by heating and then transferred to the photographic paper to generate an image.

Dye sublimation printing uses thermal induction technology, and during printing, YMCO (yellow/pink/cyan/protective film) three-color dye and a layer of protective film are vaporized in turn through heat treatment and then imprinted on special photo paper. The source of color dyes s generally divided into yellow, magenta, and cyan ribbons plus protective film or four color bands of yellow, magenta, cyan, and black.

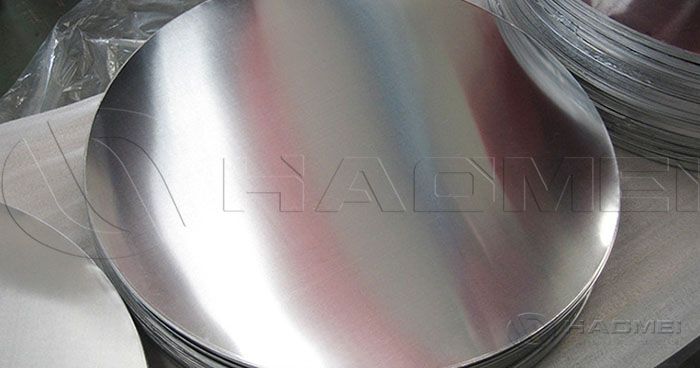

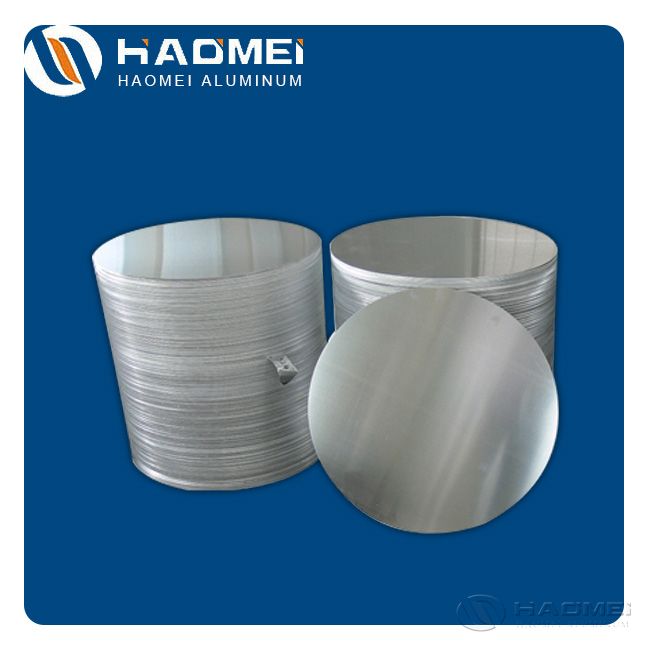

With the advancement of sublimation transfer technology, sublimation transfer paper has begun to be used in the field of hard materials, including copper plate, round aluminum sublimation blanks, wood board and temperature-resistant plastic plate. The untreated hard materials have poor color-fixing effect and low printing accuracy. Usually, the hard materials need to be pretreated.

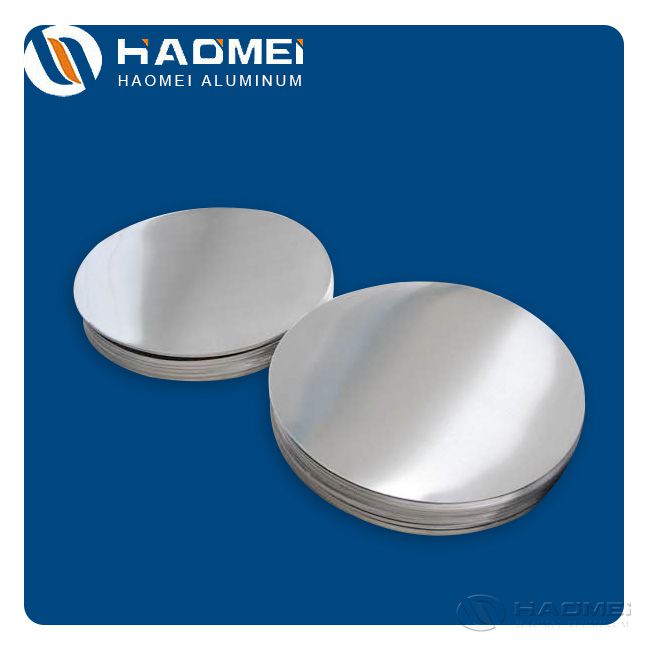

Sublimation blanks are specially manufactured products designed to customize or personalize with graphics with the sublimation printing process. They are heat resistant because the print image gets transferred from the paper onto the substrate under high temperature and recommended pressure. The substrate must be white or or light-color for customization printing.

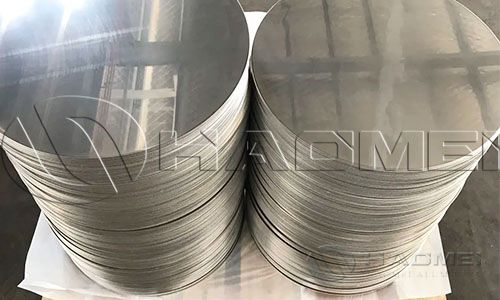

As one of the big aluminum circle suppliers, Haomei Aluminum has different types of aluminum circles for you. Welcome to leave message below to inquire what you need.

Original Source: https://www.alumhm.com/a/round-aluminum-blanks-for-sublimation.html