The aluminum trim strip is usually a kind of color coated aluminum strip, adopting a two-coating and two-baking process, that is, after the surface pretreatment of the aluminum coil, the primer (primary coating) and topcoat (finishing coating) are applied and baked twice. It can carry out back coating and embossing or printing processing as needed.

One of its main application is ceiling. In suspended ceilings made of mineral fiber panels, colored aluminum strip can enhance the decorative appearance of the ceiling support structure. This narrow, thin coated aluminum strip is often used to cover the surface of T-rails. The aluminum strip ceilings are being manufactured in different widths and at any desired length.

According to the type of coating, pre-coated aluminum coils can be divided into two categories: PVDF coated aluminum coil and PE coated aluminum coils. Fluorocarbon pre-coated aluminum coils are aluminum products with excellent weather resistance, UV resistance, chemical corrosion resistance and self-cleaning properties.

Polyester pre-coated aluminum coil refers to coating the surface of the aluminum coil with coating containing polyester resin to form an aluminum product with good adhesion, rich colors and environmental protection performance.

It consists of a three-layer structure, namely aluminum alloy substrate, aluminum oxide film and coating. The aluminum alloy substrate is the supporting layer of colored aluminum, which provides the strength and toughness of colored aluminum. Generally, 3000 series or 5000 series aluminum alloys are used. The coating is a decorative layer of colored aluminum that is cured at high temperatures and can appear in various colors and patterns.

The roller coating method refers to applying the organic coating evenly on the aluminum coil through a roller coater after pretreatment on the surface of the aluminum coil, and then through drying, solidification, cooling and other processes to form a color coating with a certain thickness and performance. The roller coating method can achieve single-sided or double-sided color coating, or multi-layer or multi-color color coating to meet different needs and effects.

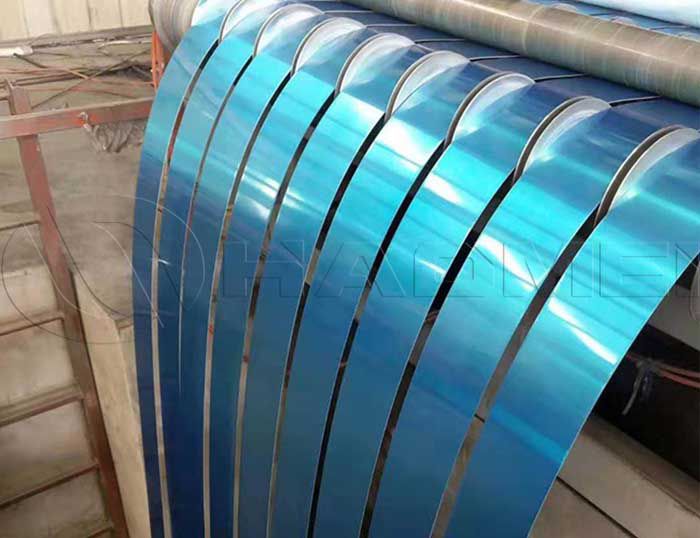

The color coated aluminum strips for sale are processed from aluminum coils through slitting equipment, so the processing thickness and tolerance of the aluminum strips are closely related to the slitting equipment. Our aluminum flexible strip slitting equipment comes from Germany, which can effectively control the width tolerance. The tolerance can be controlled within 0.05mm. Currently, it can slit aluminum strips with a thickness of 0.15-3.0mm, ensuring no scratches and accurate width tolerance control.

Original source: https://www.aluminumstrip24.com/news/what-is-aluminum-trim-strip.html